Engineering

Mjørud operates in a high-tech engineering environment, using state-of-the-art software. We have a continuous development of computational models and proceedures to maintain control of all design processes.

With our long experience in design and analysis, we construct solutions with proven document supported service life by the use of software packages e.g.: AUTODESK INVENTOR, ANSYS MECHANICAL, ANSYS CFX, HTRI, Mathcad, STAAD-PRO, etc.

With our effective design and production methods, we are a trusted and reliable partner for oil and gas industry operators. We understand our customers' challenges and can provide solutions for serial or customised production. Mjørud is known for fast response, reducing downtime and improving availability for client systems.

Challenges to consider when dealing with heat stressed components and systems

- Inlet boundary conditions

- Gas temperature

- Gas mass flow

- Convection figures

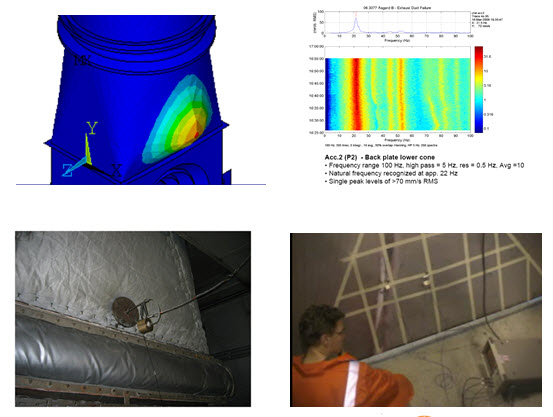

- Resonant frequency

- Vibration levels

- Global analyses

- Local analyses

- Life time

- High cycle fatigue

- Low cycle fatigue

- Environmental loads

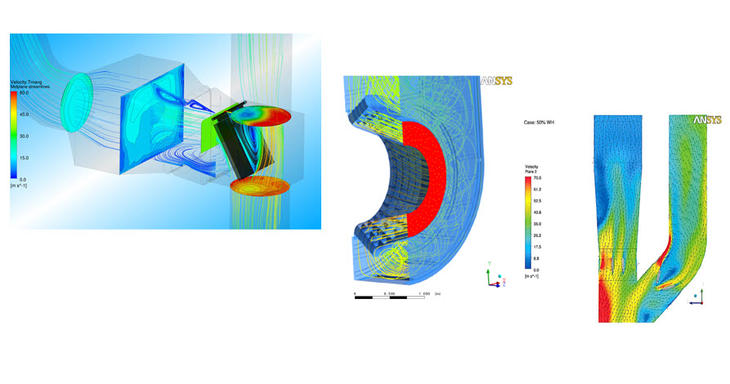

Flow analysis

- Flow Analysis - an essential tool for correct loading to calculations and design

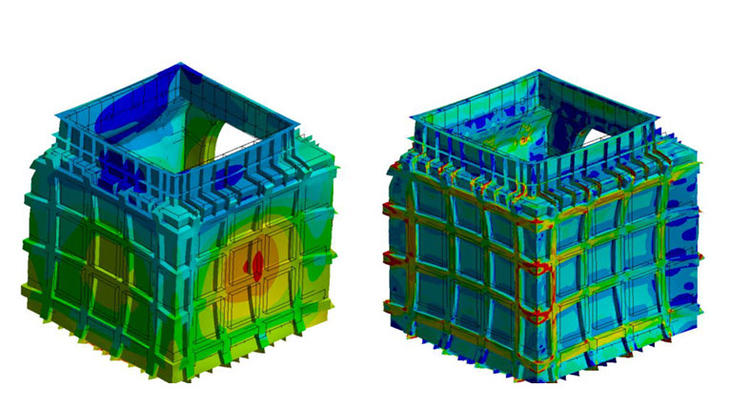

Structural Analysis

- Combined analysis (FSI) taking mechanical, thermal and flow induced loads into considderation.

Example for Case studies

- LM2500 Gas Turbine

- Bleed air flow simulation

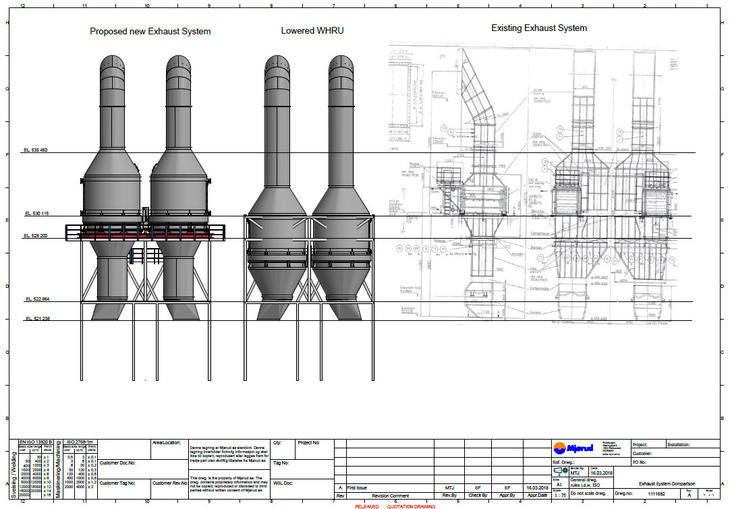

Typical case for Exhaust system study - upgrade and replacement

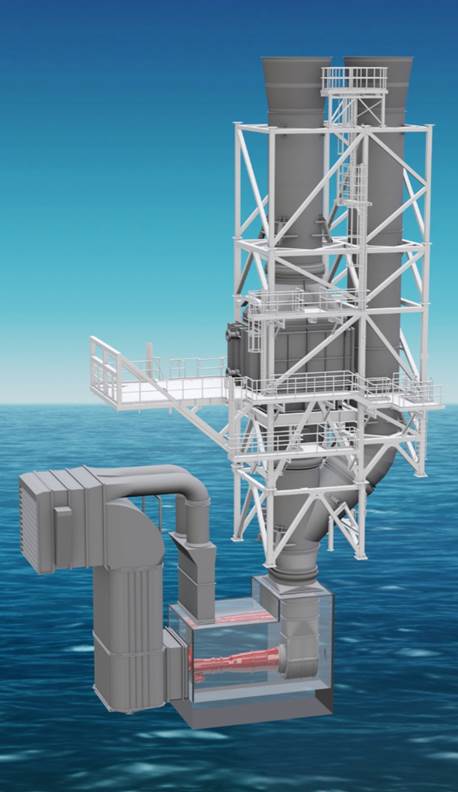

Our core engineering and production focus is related to Gas Turbine installations:

- Air inlet

- Filter house

- Inlet silencer

- Inlet plenum

- Anti Icing system

- Turbine enclosures

- Turbine ventilation

- Driven equipment enclosure

- Exhaust collector

- Bleed air systems

- Exhaust duct system

- Diverter valve and MLD

- WHRU / HRSG systems

- Structural support systems

- Turbine handling equipment